Summit Systems: Why You Should Choose a Twin Gravimetric Dosing Unit

With the Plastic Packaging Tax on the horizon, and the need to increase your recycled content, leading ancillary supplier Summit Systems discusses why you should consider the Movacolor twin gravimetric doser above standard gravimetric and volumetric models.

We all know the beneficial differences between the gravimetric and volumetric dosers, weight vs volume, automatic vs manual speed settings…but what about twin gravimetric dosing?

The MCBalance (gravimetric) and MC12 (volumetric) doser ranges from Movacolor were developed for in-line additive dosing at the desired speed in the mainstream of an injection moulder or extruder. Both dosage systems are complete with a hopper, neckpiece, controller, stepper motor, and dosage cylinder or screw feeder.

In terms of speed, the stepper motors range from 0.1 to 200 rpm and therefore can be set very accurately.

In addition, the unique Movacolor dosage cylinder makes sure the additive is dosed in-line in a nice smooth flow of material without pulsations, which produces an output of consistent quality.

Why should you consider a twin gravimetric doser?

The MCTwin gravimetric dosing unit from Movacolor, the finest on the market, simultaneously doses additive and regrind. One dosing unit functions as the main unit and doses the regrind, while the second operates in conjunction with the main unit, dosing the additive.

Key features:

- Continuous loss-in-weight measuring.

- Automatic colouring correction depending on recycled material.

- Ultra-compact three-component system.

- Direct mounting onto the machine throat.

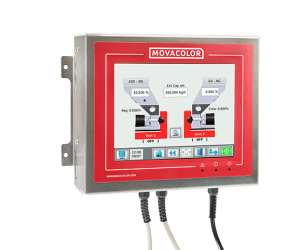

- 8” full-colour touchscreen with smart software.

- Integrated hopper loader control.

- The unique modular system allows for extra units to be added.

- Industry 4.0 ready.

Using a closed-loop function, the sprues from the injection moulding operation are directly fed back into the process, and the amount of additive added is automatically adjusted to the availability of the regrind, resulting in higher cost savings.

Helping you to avoid the overconsumption of additives and reuse the maximum amounts of regrind, the MCTwin unit is fully automatic, so you’ll always dose the maximum percentage of available regrind.

The functionality of dosing regrind in combination with the additive makes the MCTwin a sustainable solution for your production procedures.

Why choose a MCTwin?

- Greater return on investment over a long-term basis.

- Higher precision feeding system.

- Easy operation using the touch screen controller.

- Accurate close monitoring of production process.

- Increased savings on expensive additives.

- Reduce downtime by quickly identifying any errors in the production process.

- 100% control over the quality of your product.

Why choose Movacolor?

Movacolor’s leadership in dosing technology is based on more than 30 years of partnership with plastics producers worldwide. It was added to the catalogue of ancillary equipment supplied by Summit Systems in 2006, “As the world leader in gravimetric dosing machines, once we added Movacolor’s products to our offering we experienced phenomenal growth compared to volumetric counterparts,” recalled Mike Jordan, Managing Director.

The gravimetric models continue to increase in popularity, and Summit strongly believe that with the introduction of the Plastic Packaging Tax, this technology from Movacolor could not be more pertinent. Adding one of these dosing units to your plastic manufacturing plant will increase efficiency, quality and return on investment.

Summit Systems is the exclusive UK distributor for Movacolor. For further information on how you can upgrade your line with a Movacolor doser, get in touch with Summit Systems using the details listed below.

Summit Systems

+44 (0)1827 265 800

Website

Email