Connect with Wittmann 4.0 at Interplas 2023

WITTMANN BATTENFELD UK will present its largest portfolio of products and services to date at the UK’s upcoming Interplas 2023 exhibition.

Joint MDs Tracy Cadman and Dan Williams say that topics of connectivity and Wittmann 4.0 will play a central part in the company’s presence there.

‘The online and connected worlds are a common part of everyday life, and fast becoming more present and easily accessible within manufacturing facilities,’ says Dan. ‘WITTMANN BATTENFELD UK has held open houses on the Industry 4.0 topic several times in the past, with Wittmann pioneering full integration of all our products and auxiliaries for many years. We fully understand the issues, aspirations and realities of our customers and want to ensure that they fully benefit from what Wittmann can offer them, saving them energy, time, and materials.’

Dan adds that ‘from the beginning, Wittmann has developed smart injection moulding machines and has then moved forward to developing the smart production cell.

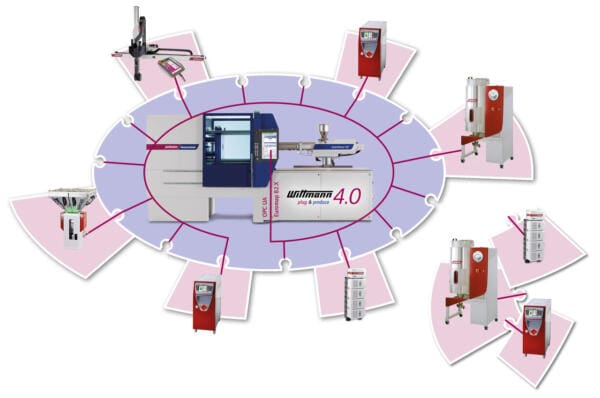

We see ourselves in an incredibly unique position within the injection moulding industry as the only company worldwide able to fully integrate all of our auxiliary equipment (robots, material handling, dryers, granulators and blenders) – and use all such data to optimise the performance of the customers work cell.’

Wittmann 4.0 is the result of borrowing the 4.0 suffix from Industry 4.0 – named for the 4th Industrial Revolution. In brief, Industry 4.0 stands for the synthesis and networking of all relevant technologies in an Internet of objects, services and data – integrating, directing and improving manufacturing systems in order to be able to offer quick, flexible responses to customer demands.

Tracy points out that ‘since we make and supply everything that could possibly be needed in an injection moulding production cell it was completely natural and logical for us to explore and optimise the ways in which all the equipment could effectively interact with itself.’

For plastics processors, Wittmann 4.0 opens up the prospect of an unparalleled degree of transparency, traceability, productivity and process management – not only for the profits of business owners but also in more accurate servicing of the needs of their customers and beyond.

Dan says that ‘users of our Wittmann 4.0 systems report that it represents a quantum leap away from the traditional ‘mix and match’ approach to moulding; putting various different pieces of equipment together, most likely on the basis of price alone.’

Instead, more and more WITTMANN BATTENFELD UK customers are reaping dividends by investing in connected systems such as Wittmann 4.0.

Tracy says that ‘Wittmann 4.0 has itself been created both for optimal production security and also for immediate ‘plug and play’ capabilities.

Wittmann 4.0 connects to our Manufacturing Execution System (MES), TEMI + – developed expressly for plastics processing needs. TEMI + connects the moulding machine to all ancillary equipment and any alterations in the composition of the moulding cell are recognised automatically within the cell, with all technology placed on a secure and digital platform.’

Visit the WITTMANN BATTENFELD UK team at Interplas in Hall 3A, stand CC10

For more news from WITTMANN BATTENFELD UK, click here.

WITTMANN

01933 275777

Website

Email