Wittmann Battenfeld to Present its Pioneering Technologies at K 2022

Circular economy, digitisation and climate protection – the hot topics of this year’s K fair are also the hot topics of the WITTMANN Group’s machinery presentation. With applications shown at the WITTMANN BATTENFELD booth C06 in hall 15, at the VDMA Circular Economy Forum, at booth -CE10 in the outdoor area, and more equipment presented at the booth of WITTMANN Technology as well as several booths of other exhibitors, WITTMANN BATTENFELD will give visitors to the K fair insights into its extensive range of ultra-modern, resource-saving technologies.

Under the motto of “It’s all WITTMANN”, WITTMANN BATTENFELD will present its machinery and equipment at this year’s K fair for the first time in the new WITTMANN design, thus demonstrating even more clearly than before the WITTMANN Group’s competence as a single-source supplier of complete injection moulding systems, which includes not only the machine but also automation and auxiliary equipment with the option of Wittmann 4.0 integration. It’s all WITTMANN also means latest application technology targeting highest quality standards and functionality combined with the smallest possible CO2 footprint.

Our trade fair highlight – EcoPower operating with direct current generated from sources of renewable energy: solar, wind and water power.

Solar cells on corporate roofs offer companies the possibility to generate their own electricity and thus not only to save costs but simultaneously protect the environment. An answer has been found by WITTMANN BATTENFELD together with its customer WAGO to the question of how the continuous current generated by solar cells can be used directly for driving injection moulding lines, without loss by first passing through inverters, transformers and high-voltage power lines. By way of a conceptual study using a machine from its all-electric EcoPower series, WITTMANN BATTENFELD has demonstrated the solution and applied for a patent jointly with WAGO. On an EcoPower 180/750+ operating with direct current, a part for the customer’s “basic clamp” is produced from flame-retardant polyamide with a 24-cavity mold supplied by WAGO. The parts are removed by a modified WX142 robot from WITTMANN in a DC version powered directly via the intermediate DC circuit of the EcoPower, and which also returns any excess energy set free by axis deceleration to the intermediate circuit.

This concept not only enables energy costs to be kept down by direct use of solar electricity, but direct current is also easy to store in conventional batteries, thus providing an excellent way to handle current peaks. If necessary, the machine can be changed over to AC operation.

The EcoPower 180 comes with the new B8X control system equipped with system components developed in-house. These enable a higher internal clock frequency, thus ensuring shorter response times to sensor signals and consequently higher reproducibility of parts, together with unchanged user-friendliness and the familiar visualisation.

Energy-efficient and eco-friendly production with multi-component technology

WITTMANN BATTENFELD can draw on many years of experience in multi-component technology. At this year’s K fair, the company will demonstrate its expertise in this area by the production of a reusable 3-component coffee-to-go cup. This application will also show the advantages and quality improvement achieved by a combination of processes. In addition to multi-component technology, Cellmould structured foam technology will be used to reduce the material input.

In this application, a cup with a lid made of BornewablesTM from Borealis is manufactured on a servo-hydraulic SmartPower 400/750H/210S/525L Combimould with a rotary unit and a mould supplied by HAIDLMAIR, Austria. The BornewablesTM material made of renewable raw materials (i.e., non-petroleum-based feedstock) enables Borealis to meet the quality and sustainability standards required by WITTMANN. The material is food- and dishwasher-safe as well as ISCC PLUS-certified (International Sustainability & Carbon Certification). The feedstock for making Borealis BornewablesTM originates from bio-mass, waste and residual substances of the second generation, which are not in competition with the human food chain. Product safety and performance features are on a par with those of modern polyolefins, with a simultaneous significant reduction of the CO2 footprint. The mould from HAIDLMAIR is laid out optimally for processing BornewablesTM material. A special feature of this mould is the use of hybrid elements in the mold plate to optimize cooling. These hybrid elements are manufactured by HAIDLMAIR directly on a laser tech machine in one production step from a combination of conventionally processed tool steel with 3D-printed yellow bronze.

The cup produced in clear optic in the first cavity is over-moulded in the second cavity with a shell and provided with an additional insulating effect by foaming the melt with Cellmould technology. The shell consists of a BornewablesTM PP blend with adequate surface attributes for a firm grip. The lid for the cup is injection-moulded in an adjacent cavity. It consists of the same material as the main body, but can be individually coloured thanks to the special mould technology. The choice of materials was made to suit the cup’s function and give it a clear optical appearance. So, the entire cup is not only produced from BornewablesTM, but can also be both re-used and 100% recycled in line with the principle of circular economy. The parts are removed and deposited on a conveyor belt by a WX142 robot, then passed on to a flow wrapping machine and packaged. The packaging material used in this instance also comes from the BornewablesTM product family from Borealis.

Processing of alternative materials

Processing of alternative materials, especially renewable and recycled materials, presents a special challenge due to the viscosity fluctuations which such materials undergo during processing. WITTMANN BATTENFELD solves this type of problem by using HiQ application software, which is continuously evaluated and further improved in order to ensure highest quality standards in processing these materials, too.

At this year’s K fair, WITTMANN BATTENFELD will present two more applications where renewable materials are used. In both cases, the machines are equipped with the HiQ Flow software, which compensates viscosity fluctuations in the material.

One of these applications will be shown at the WITTMANN BATTENFELD booth C06 in hall 15. It is a bio-degradable ice-cream cup, manufactured with a 6-cavity mold supplied by Precupa, a high-precision mould-making specialist based in Germany. The parts are produced on an EcoPower 110/750 equipped with the new B8X control system. The material used is BAOPAP from HopeTree, Germany, consisting of water, vegetable oils and fats, starch, vegetable thickening and swelling agents and natural fibers, and is entirely free of chemical substances. It is disposable via the organic household waste can, with the material being decomposed completely and without residues within 50 days at the most. Its attributes recommend it as an ideal substitute for cardboard. This material can be fed into the injection moulding process directly without pre-drying. Downstream finishing is also dispensed with. The parts are removed and deposited on a conveyor belt by a W918 robot from WITTMANN.

The second application in which a renewable material is used can be found at the VDMA Circular Economy Forum, outdoor area, booth -CE10. In this application, a bio building block made of Fasal is manufactured on an EcoPower 110/350 with the new B8X control system, using an 8-cavity mould supplied by Bioblo, Austria. This raw material is a compound made by Fasal Wood GmbH, Austria, from wood flour and post-industrial polypropylene supplied by Borealis, Austria. The equipment is designed as an Insider cell, which has a W918 robot and an S-Max 3 screenless granulator from WITTMANN, a conveyor belt and also the protective housing all integrated in the production system. The moulded parts and the sprue are removed by the W918 robot, and the sprue is passed on directly to the granulator, where it is ground and then returned to the process. The finished parts are deposited on the integrated conveyor belt, transported to a flow wrapping machine and packaged. The tubular packaging bags are made of the BornewablesTM FB4370 material from Borealis.

To ensure top quality for the parts, the software packages HiQ Metering for active closing of the check valve and HiQ Melt for measuring the MFI are used in addition to HiQ Flow. The resulting MFR (melt flow rate) is an indicator of the material’s flow attributes.

Injection-compression moulding for thinner wall thicknesses

In injection-compression moulding (ICM), the melt is injected into a not yet completely closed mold. Final forming of the part takes place following complete closing of the mould by displacement of the melt into the cavity. This enables the mould to be filled under lower pressure, which in turn leads to a reduction of warpage inside the part. Injection-compression moulding allows processing of an extended range of materials with particularly high efficiency in material and energy input. Moreover, it offers innovative approaches to solutions where conventional processes have reached their limits. This process enables the production of extremely thin, precisely reproducible wall thicknesses and accurate reproduction of surface structures.

WITTMANN BATTENFELD will demonstrate this technology on a high-speed EcoPower Xpress 160/1100+. With a 4-cavity mould supplied by GLAROFORM, Switzerland, a 230 ml cup made of polypropylene from SABIC, the Netherlands, with a wall thickness of 0.28 mm will be produced within a short cycle time. Thanks to the highly dynamic drive technology of the high-speed EcoPower Xpress, especially the short injection times required for the ICM process can be realised. The machine is equipped with a 4-fold IML system supplied by BECK Automation, Switzerland. This system stands out by its high speed and compact design. One of its special functions is automatic positioning of all four labels. Regardless of its position inside the magazine, every label is invariably placed into exactly the same position on the IML core. This reduces both reject rates and operating effort, since manual adjustment of the label magazines is no longer necessary. Quality inspection of the cups decorated with IML labels supplied by Verstraete, Belgium, will be carried out by a vision system with 10 cameras integrated in the production line, which comes from INTRAVIS, Germany.

Saving resources and reducing weight with alternative materials plus ultra-modern equipment and process technology

With a MacroPower1100/12800 fitted with an energy-saving, speed-controlled servo motor and a constant displacement pump, WITTMANN BATTENFELD will produce an indoor panel which stands out by its light weight, using a single-cavity mould supplied by FRIMO, Germany. Here, WITTMANN BATTENFELD relies on using natural and recycled materials. The door panel consists of an extremely light mat made of natural fibers, onto which a map pocket made of polypropylene regrind from Borealis is over-moulded. To achieve further savings in material input and weight, the patented Cellmould structured foam technology developed by WITTMANN BATTENFELD is used. The reduction in material input thus realised benefits the environment in more than one way. Firstly, valuable resources are saved, and secondly, the parts are lighter, which reduces the car’s fuel consumption and/or extends the battery range in electric vehicles. In this application, the pre-cut natural fiber mats are picked up from a buffer stack and inserted into an IR heating station by a WX152 robot from WITTMANN. Next, the heated mats are placed into the mould on the fixed mould half by a combination gripper (removal and insert gripper), formed, cut to size and over-moulded. Prior to insertion of the next natural fiber mat, the finished part and the trimmings are removed from the fixed mould half and subsequently transported to the storage position.

MacroPower 1100 with a mold supplied by FRIMO (photo: FRIMO)

The MacroPower is equipped with the newly developed WITMANN CMS Lite condition monitoring system. This system continuously checks the state of health of the servo-hydraulic axes, from which the condition of the pump and axis valves can be derived.

New SmartPlus with high-tech automation and digitisation

At this year’s K fair, WITTMANN BATTENFELD will present an outstanding demonstration of its digitisation and automation expertise by manufacturing a spirit level on a machine from the new SmartPlus series with the new B8X control system. Special features of the servo-hydraulic SmartPlus are high levels of cost and energy efficiency and repeatability. By using proven technologies combined with carefully selected options, it has become possible to offer an excellent price/performance ratio for these machines.

On a SmartPlus 90/350 equipped with the CMS Lite conditioning monitoring system and an automation cell designed and manufactured by WITTMANN BATTENFELD Germany, a spirit level made of ABS is produced with a 1+1-cavity mould supplied by SOLA, Austria. As a first production step, the top and bottom parts of the spirit level housing are injection moulded. The top part is then deposited and printed at a laser station. Simultaneously, the bottom part placed on a tray is fitted with vials from SOLA. Next, the top part is pressed onto the bottom part by a pre-set force. The finished parts are then transported to a testing station, where the positioning of the vials is checked by a vision system. After quality inspection, the finished spirit levels are removed and deposited on a conveyor belt by a WX138 robot from WITTMANN.

Standard and micro liquid silicone processing

Silicone processing is one of WITTMANN BATTENFELD’s core competencies and will be demonstrated at this year’s K trade fair on two exhibits.

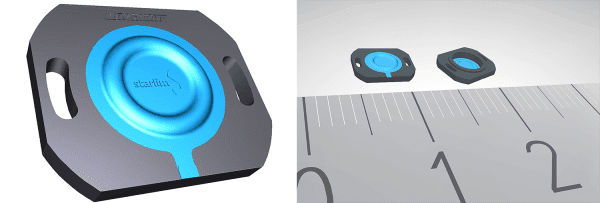

The second LSR application to be presented at the K is production of a membrane for a high-quality micro loudspeaker made of thermoplastics and liquid silicone, manufactured on a MicroPower15/10H/10H Combimould with a single-cavity mould supplied by Starlim Spritzguss GmbH, Austria. The choice of a single-cavity mould serves to demonstrate the high precision of the mould in combination with the machine, which is specially designed for the production of micro parts. It is often necessary to build costly multi-cavity moulds already at the prototyping stage for the sole purpose of reaching the necessary minimum throughput of the machine. The MicroPower is equipped with a 2-step screw-and-plunger thermoplastic aggregate and a 2-step screw-and-plunger LSR aggregate. The LSR metering pump supplied by EMT Dosiertechnik, Germany, is a 1-liter cartridge system developed for extremely small metering volumes. Smooth, continuous emptying of the cartridges ensures highest precision together with consistent quality. Another advantage is the blending section reduced to a minimum, with the special benefit of rapid cleaning and minimal material loss with every material changeover.

Saving resources with light-weight technology

In addition to its exhibits of machinery and equipment, WITTMANN BATTENFELD will also present its latest developments in Airmould internal gas pressure technology. The items to be showcased are the new Airmould 4.0 pressure control module and the new manual operating unit for this technology. At an Airmould / Cellmould Center, expert engineers from the company will be on site to advise visitors concerning the use of Airmould technology and Cellmould structured foam technology. Both of these technologies enable significant reductions of material input in the production of plastic parts, with a simultaneous positive effect on part weights and production costs.

Focusing on energy consumption

All machines shown at the WITTMANN BATTENFELD booth as well as the IMD/IML application on a SmartPower exhibited at the WITTMANN booth and the EcoPower machine presented at the VDMA Circular Economy Forum are equipped with the IMAGOxt energy management software. IMAGOxt is a proprietary development from WITTMANN Digital Srl., previously ICE-Flex Srl. / Milan, Italy, which provides scalable display and visualization of the energy consumptions of the machines and equipment connected. The program also calculates directly the CO2 consumption and energy savings already realized. All values calculated can be documented in reports and thus remain available for long-term analyses. This program is available as a web application either in the form of an optional extension to the TEMI+ MES program from WITTMANN or as a stand-alone program.

At a TEMI+ Expert Center specially created for this purpose at WITTMANN BATTENFELD’s K fair booth, visitors to the fair will have an opportunity to gather detailed information about the TEMI+ MES program and the IMAGOxt energy management software, as well as to receive advice concerning energy management improvements and resulting cost cuts for their own company.

Machines at the WITTMANN booth – hall 12, F23

WITTMANN HoloVerse – voice control and mixed reality

At the K fair 2022, WITTMANN will show a comprehensive study about modern possibilities of intuitive interaction with injection moulding machines and parts removal robots. In a research project conducted over several years, the possibility of voice and gesture control of a WITTMANN BATTENFELD injection moulding machine equipped with a B8 control system and a WITTMANN robot with an R9 control system has been developed. The work cell, to which voice control and augmented reality have been added, consists of a SmartPower 120 and a W918 robot.

IMD / IML technology for decorated and functionalized surfaces

At its booth in hall 12, WITTMANN will present a manufacturing line to make decorated and functionalized surfaces. This is a joint project of the companies WITTMANN BATTENFELD, LEONHARD KURZ, a producer of functional films and film feeding equipment, and SYNTECH PLASTICS, a supplier of IMD technology. The equipment is laid out flexibly to accommodate IMD with a feeding unit, IMD with film pre-heating, IMD Vario with pre-heating and thermoforming, as well as insert molding. It includes a SmartPower 300 machine, a W846 robot with a fixed demoulding axis and specially developed gripper technology, together with WITTMANN auxiliary components, IMD components from KURZ, and hardening and cleaning technology supplied by Baier. The SmartPower 300 is specially equipped with the EXPERT-Coining package, which permits parallel mould movements during the injection process. On this line a close-to-series production, fully functional conceptual component for an automotive headliner will be manufactured.

Machines showcased at other exhibitors’ booths

At the booth of IKV Aachen, hall 14, C16, a stackable sorting box made of Systalen polypropylene with a colour masterbatch on 100% PCR carrier material will be manufactured on a SmartPlus 120/525 with the new B8X control system, using a single-cavity mould supplied by Kroma International, Germany. With the production of this item consisting of 100% PCR, an internal mould pressure control system developed by IKV will be presented, which ensures consistent parts quality regardless of batch fluctuations when processing post-consumer recyclates.

Another machine from the SmartPlus series, a SmartPlus 60/210, will be showcased at the booth of the Hungarian Plastics Industry Association, hall 8b, booth H79. On this machine, biodegradable coffee capsules made of water-soluble PVA and a biomaterial blend will be produced with a 4-cavity mould from Somplast, Hungary.

Read more about Wittmann Battenfeld UK here.

Wittmann

01933 275777

Website

Email