Wittmann at Plastics Live – Monitor & Save Energy with IMAGOxt

As the critical issues of energy security and pricing have understandably become urgent for all manufacturers in recent months, Wittmann will be providing cost-saving energy tips and related know-how for injection moulders at the Plastics Live exhibition, July 5-6 in Coventry.

Dan Williams, Joint Wittmann Battenfeld UK MD, says: ‘It’s no surprise that the injection moulding sector now has an urgent need to understand and to save all possible energy costs. It begins with awareness and measurement of the issues. We are very much looking forward to sharing our expertise and solutions at Plastics Live in July 2022.’

All of Wittmann’s equipment for injection moulding is designed to be class-leading in energy efficiency. However, Wittmann realised that it needed to go further – and to give injection moulders an easy way of documenting and coordinating all of the energy outputs involved in their production.

The result of this process and the answer to this need is IMAGOxt – a new energy management software (EMS) from Wittmann.

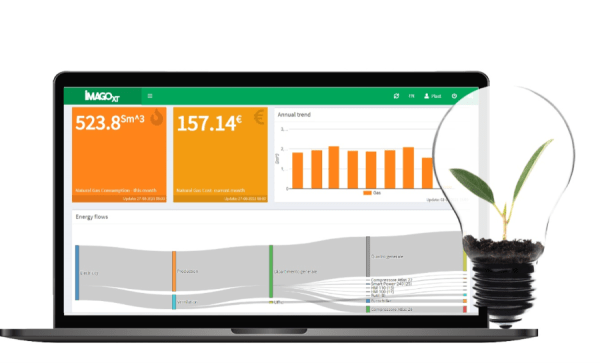

Wittmann’s IMAGOxt allows the energy consumption of connected machinery, devices and any consumption clusters in the company to be visualised and displayed in a scalable manner.

This energy data can also be aggregated into logical units to make evaluation even more straightforward. The program runs as a web application, both as an optional extension to the Manufacturing Execution Software (MES) TEMI+ from Wittmann and a stand-alone program.

IMAGOxt contains numerous functions and tools that help display current energy usage, graphically depicting historical trends and defining key performance indicators (KPIs) and consumption targets. IMAGOxt also enables measurements such as real-time energy flows between different departments or consumption clusters to be visualised. Such consumption analyses help businesses identify the actual energy consumers within the company.

The gathered data is then used by IMAGOxt, which can associate it, when integrated, with the TEMI+ system. In this way, the accrued energy costs per moulding machine can be apportioned to the individual cycle of the machine or even mapped onto specific injection moulded parts. The software allows analyses, graphical representations, reports and meaningful KPIs to be freely configured in easily intelligible, customisable dashboards. Companies can use these insights to manage their production operations more efficiently and take decisions to expand their business in an environmentally and financially sustainable manner.

The intuitive graphical visualisation depicts complex conditions in a simple and easily intelligible form. This allows energy-saving opportunities to be quickly identified and exploited. IMAGOxt helps businesses to become more sustainable and conserve resources. It also allows cost savings to be realised that safeguard the long-term growth of the company and give it an edge over competitors.

Tracy Cadman, Joint Wittmann Battenfeld UK Managing Director, says: ‘Wittmann Battenfeld UK is all about helping our customers to increased profitability: Being aware of energy consumption within your own company is the first step to identifying inefficiencies and making the necessary improvements. Simply avoiding the unproductive use of energy represents a significant potential energy-saving.’

Tracy adds: ‘We intend to give specific examples of the opportunities and savings from IMAGOxt before the Plastics Live show opens, July 5-6, 2022.’

For more information on IMAGOxt, please visit: wittmann-group.com/en/imagoxt-eco-friendly-production or contact Wittmann Battenfeld UK directly using the details below.

Wittmann

01933 275777

Website

Email