Five Moulding Opportunities in the Electric Vehicle Market // HUSKY Blog

|

Getting your Trinity Audio player ready...

|

Global Electric Vehicle sales reached approximately 17 million units in 2024, a 25% increase from 2023. According to the International Energy Agency’s Global Electric Vehicle Outlook 2024 report, China has emerged as the dominant force in this growth, accounting for nearly 60% of global electric car registrations. In 2023 alone, China registered 8.1 million new electric cars—a 35% increase from the previous year—with more than one in three new car registrations being electric. The country is also becoming a major exporter, with 1.2 million Electric Vehicles exported in 2023, an 80% increase from 2022. In this article, Husky explores five high-growth opportunity areas for moulders in the expanding Electric Vehicle market.

This rapid growth is being propelled by substantial government support, including China’s $230 billion investment in the Electric Vehicle sector and targeted industrial policies. As OEMs race to meet regulatory requirements and growing consumer demand, they’re actively seeking moulding partners with expertise that goes beyond traditional automotive capabilities.

As a result, moulders with the right expertise can capitalise on emerging supply chain gaps left by traditional supplier networks.

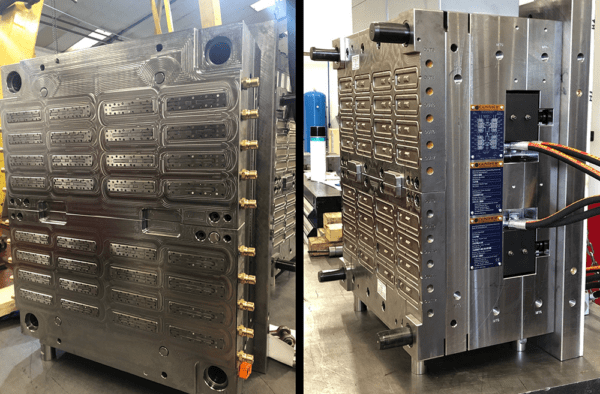

1. High-Performance Battery Component Moulding

As battery demand skyrockets, so does the need for critical plastic components that ensure battery cell integrity, safety, and performance. These include:

- Isolation rings, spacers, and spacer tops: These components play a pivotal role in maintaining the integrity of battery cells, ensuring they function optimally

- Protective enclosures, covers, and trays: Made primarily from polypropylene (PP), these components safeguard battery cells within Electric Vehicles, providing protection and insulation to guarantee the safety of both the vehicle and its passengers

- Specialised cylindrical battery components: Various components made from different materials, including PP for quality production, PBT for thermal sensitivity, and PFA for high temperatures

A key challenge for moulders entering this space is developing expertise in processing highly corrosive and temperature-sensitive materials—an area we’ll explore further in the materials processing section. Unlike traditional automotive moulding, which prioritises wear resistance, Electric Vehicle battery components require both robustness and extreme precision, demanding unique processing settings, temperatures, pressures, and speeds.

Application Spotlight: PFA Battery Rings

A leading battery manufacturer faced significant challenges processing highly corrosive PFA resin for critical battery components. Husky addressed these challenges by using a hot-to-cold gating method with 4-drop and 8-drop U750 HT-D Cap configurations. This solution minimised maintenance downtime and enabled over 1.8 million shots with substantial uptime improvement, demonstrating Husky’s capability in handling complex materials for Electric Vehicle applications.

2. Smart Components and Sensor Integration

Much like smartphones, Electric Vehicles are increasingly evolving into smart machines, integrating sophisticated electronics that are redefining the user experience with enhanced connectivity, communication, and control. This evolution is creating growing demand for precision-moulded components that support these smart systems, including:

- Sensors that provide real-time data and enable features such as collision avoidance, lane keeping assistance, and adaptive cruise control

- Camera lenses that power functions like lane departure warnings and parking assistance

- Connectors and housings that protect complex electronic systems that form the nervous system of modern Electric Vehicles

These precision components require specific materials that protect delicate electronics while providing proper encapsulation and thermal management. Success in this area, therefore, hinges on achieving both optical clarity and dimensional stability—qualities that give moulders with consumer electronics or medical device experience a natural advantage.

3. Lightweighting Solutions for Extended Electric Vehicle Range

Range anxiety remains a significant barrier to Electric Vehicle adoption, making lightweighting—reducing the amount of material used throughout the vehicle—a critical strategy for increasing driving range without requiring larger batteries.

For moulders, this creates a significant opportunity to develop thin-wall components that maintain structural integrity while minimising weight. The key challenge lies in balancing material reduction with performance requirements through sophisticated injection moulding processes that create intricate components with optimised wall thickness.

As OEMs push for every possible kilometre of added range, moulders who master these lightweighting techniques will find themselves in high demand across the Electric Vehicle supply chain. Key considerations for lightweighting in the Electric Vehicle market include:

- Applying expertise beyond batteries to interior components, under-hood parts, and structural elements

- Developing capabilities to counter the additional weight from larger battery systems

- Positioning your offerings as enablers of critical market differentiation

- Leveraging precision moulding expertise that many traditional automotive suppliers lack

4. Engineering-Grade Material Processing

The shift to Electric Vehicles introduces unique materials challenges that traditional automotive moulders may not be equipped to handle. From the corrosive nature of certain compounds to stringent protection requirements for sensitive components, producing parts for electric vehicles demands specialised material expertise.

Mastering the processing of engineering-grade polymers, for example, represents a valuable competitive advantage for moulders entering the Electric Vehicle supply chain, especially as component sophistication continues to increase with each vehicle generation. These polymers include:

- Polypropylene (PP): Valued for its chemical stability and wear resistance, particularly in battery enclosures

- Polybutylene Terephthalate (PBT): Requires careful thermal management during processing

- Perfluoroalkoxy (PFA): Demands high-temperature processing expertise

The complexity of these materials introduces significant process control challenges, requiring moulders to ensure consistent part quality even as materials risk degradation during high-temperature or extended processing.

Application Spotlight: Hot-to-Cold Three-Plate Moulding

Husky transitioned a 32-cavity PBT resin project from a cold runner to an 8-drop U500 VX hot runner system. This change reduced cycle time from 12 to 8 seconds – a 33% reduction. The optimisation reduced the required moulds from 44 to 29, significantly enhancing production efficiency, and reduced the cold runner weight by 76%.

5. Production Efficiency Without Sacrificing Quality

As the Electric Vehicle market continues to expand, moulders must meet increasing volume demands while maintaining the highest quality standards for safety-critical components. Leading OEMs are prioritising partners who can achieve both—driving a shift toward advanced process control and real-time quality monitoring.

To succeed in this space, moulders must:

- Balance high cavitation with stringent quality control

- Minimise cycle times while preserving part integrity

- Reduce material waste through precision process control

- Ensure tight dimensional tolerances for assembly and fit

- Maintain mechanical strength and consistent part filling

Moulders that leverage real-time monitoring and automated process adjustments will gain a competitive edge—delivering the scale, efficiency, and precision that Electric Vehicle manufacturers demand.

Read more news from KraussMaffei here.

KraussMaffei

+44 (0) 1925 644100

Website

Email