Many companies are choosing to go British right now for a multitude of reasons. In this blog, Plunkett Associates explores the positives of UK manufacturing.

In the past, the Far East was utilised as a production solution, almost without question and was a recognised source of ‘cheap’ manufacturing for many businesses.

In recent years, the fluctuating economy and uncertainties associated pre and post-Brexit marked the start of a change in attitude towards overseas manufacturing as bit by bit it no longer seems such a financial slam dunk to have production carried out in the Far East.

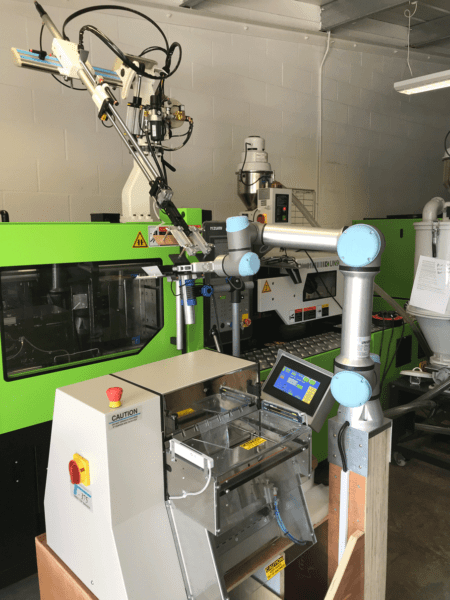

UK tooling and moulding has often been categorised as ‘too expensive’ or ‘too slow’; however, this attitude has started to change in recent years driven by an increasing awareness of environmental issues, travel and shipping issues and a more widespread introduction of automation within UK manufacturing.

Tool costs vary considerably depending on the geometry and quantities being manufactured; however, there are ways to address some of these factors or at least mitigate them.

There is no such thing as one size fits all and the ability to tailor the toolmaking/moulding solution to a specific project is an important aspect that is frequently missed in a rush to the Far East.

So, having established that the costs for the tooling can be managed, it’s now time to appreciate what you get in addition to cost-effective and highly skilled tooling and moulding by ‘keeping it local.’

1. Increased communication

Firstly, when you are investing in the production of a new product or the continued development of an existing one, we all know the level of communication with your supplier and ease of their availability is vital.

Trust and a clear understanding of what you are looking for is key when considering what option to pursue. This is so much easier when you are in the same time zone and speak the same language.

Increasing the range of manufacturing options increases the need for clear communication. We save clients time and hassle by working with a huge range of processes to ensure that the optimum solution is found and that the design addresses the strength of the process rather than being at odds with it.

2. Saving time

The ability to handle a large number of tools simultaneously has long been a strength of the Far East. The sheer capacity that can be brought to bear on a project is amazing and this frequently results in shorter lead times than can be achieved through the UK.

Viewed alone, this can be seen as very attractive but starts to diminish as time is allowed for shipping samples back to the UK, the ultimate shipment of the tool (if it is being brought to the UK) and subsequent modifications/trials.

It must also be remembered that the tooling is a one-off, whereas the moulding will be ongoing. A shorter, more responsive supply chain basically equates to huge time savings as well as reduced inventory costs.

3. Site visits

Some of our clients choose to visit our facilities, particularly in the early stages. The fact that we are well placed just off the M5 makes getting to us easy for onsite trials if clients want to be involved. If a visit is not possible, clients are kept informed of progress every step of the way (with live links if necessary).

4. Supporting global sustainability

Awareness of our planet is a big consideration, with most companies doing what they can to ‘Go Green.’ Avoiding having to ship vast distances means a dramatic reduction in component ‘miles’, all of which helps to support global sustainability, something that is at the forefront of most companies mission statements these days.

5. No more exchange rate fluctuations

5. No more exchange rate fluctuations

It started with the uncertainty of Brexit a couple of years ago and has been compounded by the global pandemic, but the vagaries of exchange rates have had an enormous impact on our want to trade overseas. The blockage of the Suez Canal in recent weeks has only served to highlight again how fragile our shipping routes are. Uncertainty and panic, as ever, results in rising costs that are unplanned and not budgeted for and if they can be avoided, keep the accounts department a lot happier.

Dealing with us means the quote you get is not going to change because of global events out of your control – simple.

6. Quantity flexibility

Many of our clients love the fact that they can call off smaller stock quantities as opposed to having to plan around a strict 6-week shipping schedule from the Far East. We offer clients the option of us holding stock for them, which provides a much more flexible ordering facility and ease of cash flow which again keeps the accounts in order!

7. Management processes reassurance

We are aware that many clients require their suppliers to be regulated for quality and control purposes. As an ISO 9001:2015 Quality System certified supplier, we have the knowledge and experience to supply the perfect solution for your plastic parts across all quantities. Isn’t it reassuring to know our management system processes are all in place?

8. Design support & analysis

We believe the added support we offer our clients with their tooling and moulding requirements is second to none. Our specialist design support and the variety and flexibility of tooling and moulding options we are able to offer is key to successful parts and a project being delivered on time and to budget.

Plunkett Associates can offer support on Solidworks to generate a design from your concept or interface requirements.

In addition, we regularly use moldflow analysis so that new part designs can be analysed immediately for manufacturability. This includes not just the ability to mould a part but also the quality of the resulting part, both physically and aesthetically. The advantages of moldflow are many, and the ability to see how a manufacturing process will work before a financial outlay has been committed to tooling is priceless.

9. Experienced and highly skilled toolmakers and moulders

We are pretty confident we are making a difference in being able to respond to clients’ needs and have already established a track record of optimising tooling solutions to meet specific requirements with regards to quantities, geometries and speed.

In addition to making steel tools, our toolmakers are highly skilled at using tooling grade aluminium for lower volume tools, which reduces both cost and manufacturing time for our clients.

Our moulders go above and beyond, too. Moulding a handful of parts is very different from 100,000 parts, but as specialists in low volume quantities, this is something we can help you with as well as higher volume requirements.

10. Proactive support and added value

We take great pride in what we do and we believe that forming a relationship with our clients is key to a great working outcome. We do our best to go the extra mile and are proactive to help improve both the quality of product and the services we can provide, continually looking ahead with regular conversations about future requirements and how we can support their needs best.

UK manufacturing has really shown what it’s made of over this past year, with many companies, including ourselves, rising to the challenge in the early days of the pandemic and producing vast quantities of PPE equipment which at that point was vital to our NHS and healthcare workers.

Since then, the want to rely on more local manufacturers by many UK businesses has brought an increased sense of responsibility across the board. We’d like to think we have proven our worth over the years with regards to the quality, responsiveness and reliability of service we provide.

If you have a production requirement or are thinking of bringing your manufacturing programme back to the UK, visit plunkettassociates.co.uk or get in touch using the contact details below.

5. No more exchange rate fluctuations

5. No more exchange rate fluctuations