Introducing Termica Neo, New Thermal Simulation Software from NETZSCH

Termica Neo is a software for the simulation of the thermal behaviour and thermal safety for chemical reactions and crystallisation in solids or liquids in volumes with sizes from centimetres to meters. The main applications are materials with high thermal potential, as well as reactions of curing, cross-linking, sintering and polymer crystallisation.

Termica Neo can:

- Simulate your material behaviour at each point inside the container.

- Find out where and when the reactant’s maximum temperature or conversion rate is inside the container.

- Determine the temperature, conversion, concentrations for a given time and position of the reactant inside the container.

- Predict your degree of curing, decomposition, crystallisation.

- Determine thermal safety conditions for production and storage.

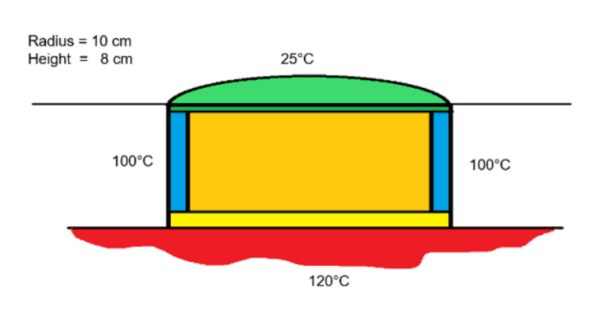

Curing in Cylindrical Container

Curing of epoxy in a cylindrical aluminium containers with different container thicknesses (from 0.3 to 1 cm) and different temperature conditions on each surface. Bottom temperature is 120°C, side temperature is 100°C, top temperature is 25°C. We can find out if the material is cured completely everywhere in this volume after waiting time of 130 min.

Curing of epoxy in a cylindrical aluminium containers with different container thicknesses (from 0.3 to 1 cm) and different temperature conditions on each surface. Bottom temperature is 120°C, side temperature is 100°C, top temperature is 25°C. We can find out if the material is cured completely everywhere in this volume after waiting time of 130 min.

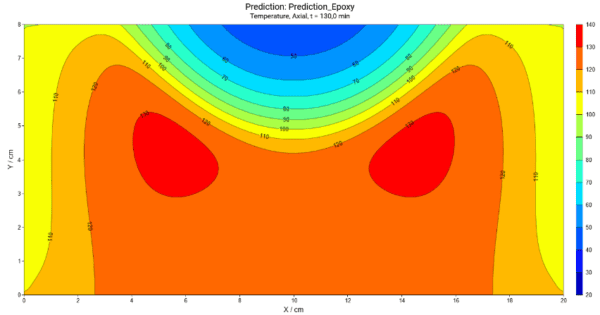

Simulation results: Temperature distribution for the vertical cross-section at a time of 130 min.

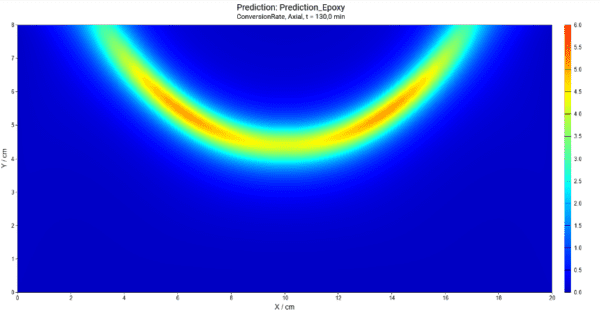

Simulation results: Conversion rate distribution for the vertical cross-section at a time of 130 min.

Simulation results: Degree of conversion for the horizontal cross- section at 50% of sample height and a time of 100 min.

The blue middle part in the middle means low degree of cure neat the vertical axis. The red parts with the maximal radius means the complete curing near the side surface.

The blue middle part in the middle means low degree of cure neat the vertical axis. The red parts with the maximal radius means the complete curing near the side surface.

The software has the possibility to see the cross-section at each user-selected vertical position if the cylinder.

What Makes Termica Neo So Valuable

- Fast and easy-to-handle by user interface similar to Kinetics Neo.

- The kinetic modes are taken directly from Kinetics Neo project (results of any method including both model-based and model-free).

Calculation of the following properties at each point of volume as a function of time:

- Temperature,

- Conversion,

- Conversion rate,

- Concentrations,

- Glass transition temperature

Calculation of Self-Accelerating Decomposition Temperature (SADT) under various materials, containers and surroundings.

Simulation of reactions for a reactor with container including adiabatic conditions

Find more news from NETZSCH here.

NETZSCH

01902 306645

Website

Email