Pure PP film, in all forms, is fully recyclable and does not produce any toxic or harmful by-products when reprocessed. But it’s often not being recycled, which is a huge concern when you consider the volume in which it is produced and used. Vanden Recycling explains more…

Polypropylene, more commonly known as PP, lends itself to a variety of applications, a versatile thermoplastic polymer which can be found anywhere. This includes parts for the automotive industry, food packaging, the bottling and FMCG sectors, pipes, crates, buckets and pallets.

The food and beverage sector drives the global PP market; this is because of its use in plastic packaging, its low prices and low weight. After PET, polypropylene is the world’s second-most widely produced plastic and, among its uses listed above, it is also found as a film.

Polypropylene’s high chemical and heat resistant properties mean that it meets a variety of regulatory requirements and is predominantly used as packaging applications for the food and medical industry.

PP film is found in two forms, both equally recyclable – cast unoriented polypropylene (CPP) and biaxially orientated polypropylene (BOPP). BOPP is the favoured PP film – it possesses high tensile strength, transparency and moisture-proof properties. This makes it an exceptional replacement for its unrecyclable counterparts – cellophane and waxed paper.

Labelling polymer type over application enables PP recycling

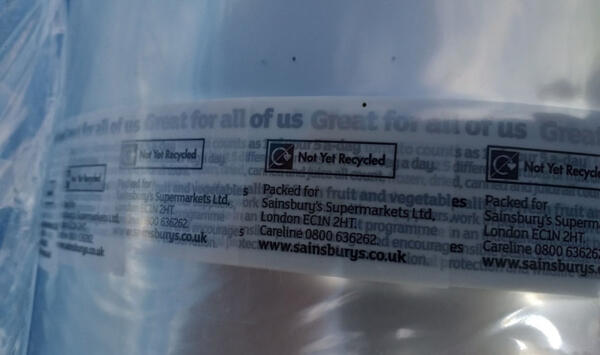

If manufacturers began to clearly label the type of film on all rolls, it would have a significant impact on the rate of plastic recycling.

Forget what you know – PP film is fully recyclable

Let us be very clear here – pure PP film, in all forms, is fully recyclable and does not produce any toxic or harmful by-products when reprocessed. But it’s often not being recycled, which is a huge concern when you consider the volume in which it is produced and used.

100,000 tonnes of PP film packaging enters the UK market each year, and its global market value is estimated to reach £109.4 billion by 2023, according to research by Transparency Market Research. The short lifespan of PP means that vast quantities is ending up in landfill, posing environmental concerns.

Often manufacturers and other generators of PP film waste have been led to believe that the default end of life for PP film is general waste. But, in reality, redundant rolls of PP film, in various forms, including printed and unprinted rolls, offcuts and skeletal waste could be recycled and provide businesses with a rebate.

How you can recover your PP film to secure a rebate

A solution needs to be implemented to recover the polymer in significant volume to ensure a sustainable source of raw materials is readily available. PP film offers great end of life flexibility, lending itself to the aforementioned applications, there is a demand for recycled polypropylene, and the market is currently underserved.

We know the recyclability of PP film is often overshadowed by its big brother, LDPE. The difference in volume means that for many years, the entire supply chain has been set up to collect LDPE film in various ways. While it is preferable to avoid combining PP in the same bale or waste stream as LDPE – as it downgrades its value – it can be baled separately or stored in a stillage or other suitable container prior to baling.

Take a look at the full range of material that Vanden trades in here.

And of course, something that we at Vanden feel extremely passionate about – segregation at source. By placing dedicated collection bins at each production line, businesses can segregate polymers early on, saving the material being unnecessarily sent to landfill or incineration, and secure a rebate.

One thing to always keep in mind is that if you can segregate anything at source at the point that it becomes waste, it has the best chance of being recycled – mixed bales and contaminated material only serve to drive down the polymer price.

If you would like to find out more information about how Vanden could partner with you to collect and recycle your PP film and skeletal waste, please contact a member of the team today.

Written by Matt Clark

Business Development Officer at Vanden Recycling

For more blog articles like this one, visit the Vanden Knowledge Centre.