The brand new AMUT DOLCI EXTRUSION line, supplied to a European customer, will produce PA-PE film to be converted into vacuum pouches/envelopes or trays for sliced foodstuff. Food application needs a multilayer film with barrier properties against gas, fats and flavourings.

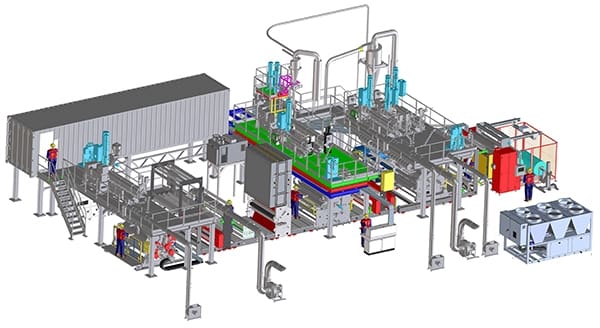

The line configuration includes 3 sections: two with flat die (cast) – one for barrier resins (PA) and one for polyolefins (LDPE, LLDPE, yonomers) – and a centrally placed lamination section where the two formed films are coated.

A barrier film with a net width of 1.800 mm and PA / Primer / Pe+Pe / Pe+Pe+ Pe formulation is obtained. The roll diameter is 800 mm and the total output is 600 – 900 kg/h depending on thickness.

Even if the formulation of produced film is quite simple, the line has great performances in terms of efficacy, efficiency and flexibility. The absolute absence of “curl-problem”, the high transparency of the film and the in-line edge trims recovery system to reduce waste at minimum represent further competitive margins, especially for vacuum pouches production.

Line composition:

First section: cast for PA barrier

Consisting of: extruder with gravimetric dosing system, automatic T-die, chill roll with 3 heated calenders, vacuum box, rolls unit for film stabilization, water-based Primer-Coating station with reverse roll system and hot air dryer, Corona treater.

Second section: cast for PE

Consisting of: 3 extruders with related gravimetric dosing systems, 3-layer feedblock, automatic T-die, chill roll with two cooled calenders.

Extru-lamination central station

Consisting of: 2 extruders with related gravimetric dosing systems, 3-layer feedblock, automatic T-die, chill roll with 3 cooled calenders, control of lamination pressure, stripping roller.

Each section is equipped with scanner for automatic gauge and film tension control. The line includes an in-line edges trimming, recovery and refeeding system and an automatic contact and gap winder, with integrated edges slitting.