HotSeat Revisited: Michael Hadfield, Group Sales Director for The Advanced Plastics Group

This week, we have a familiar face in the HotSeat. Michael Hadfield, Group Sales Director for The Advanced Plastics Group, formally MD at Protool Plastics, was last in the famous chair back in June 2018, and it’s safe to say a lot has changed since then.

What trends do you think will shape the future of UK plastics? How will The Advanced Plastics Group respond?

Environmental issues will continue to be a major focus in the plastics industry, and the drive to use recycled plastics and sustainably produced virgin grades will continue at pace.

The ‘demonisation’ of plastic is a daily headline across all news channels and social media outlets and is causing major changes of government policy that are often counterproductive to their aims when dissected by experts in CO2 emissions over various production processes.

The positive case for plastic should be an easy sell when the facts are laid out in black and white….BUT I firmly believe that the message will continually be rejected until each country recycles its own waste and not ship it around the world for disposal.

Take away the emotive issues, and the facts will become much clearer, and then real progress can be made.

The Protool Plastics Group has long been a champion of recycled polymers and actively works with customers to move away from virgin grades where possible, with some major successes.

A Fareham customer that consumes over 50 tonnes of polymer per month has transitioned from 20% to 90% recycled materials in the past 5 years and we have also introduced a post-industrial grade of PC that is now commonly used by most of our major lighting customers.

Advanced Plastics in Hull now has a zero waste to landfill goal with all plastic waste segregated and picked up weekly by a local recycling company where it is reground and resold into the plastics industry.

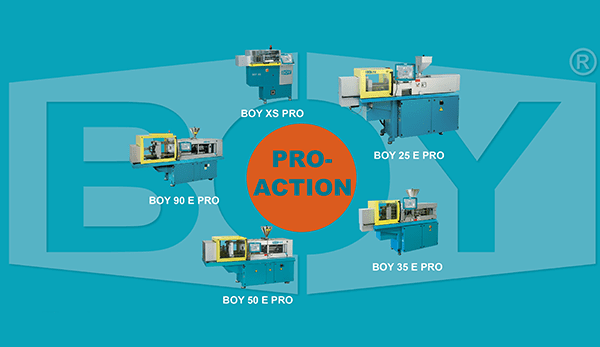

The Hull site has also firmly embraced the move to electric and low-energy usage machines with an annual replacement policy.

Other major challenges will be Artificial Intelligence and Industry 4.0, including automation, smart manufacturing and increasing levels of data that will give us valuable information to drive decision-making.

The Advanced Plastics Group has been at the technological forefront for many years, with all machines equipped with 6 axis robots and real-time production monitoring.

The expertise gained so far, and the desire to continually embrace technological advancements will keep The Advanced Plastics Group at the forefront of UK manufacturing for years to come…..advanced in approach, not just name.

How has Protool Plastics developed since you were last in the HotSeat in June 2018?

The most obvious change to The Protool Plastics Group came in 2022 when we were acquired by Advanced Plastics Limited, creating The Advanced Plastics Group.

The Protool Plastics Group saw significant growth from 2018 to 2022 with both Fareham and Manchester sites nearing capacity. With new customers continually coming on board and some existing customers seeing dramatic increases in sales the shareholders were looking at larger sites and potential acquisitions to incorporate the increase in sales.

A chance conversation with Chris Pearson in January 2022 quickly resulted in him offering to buy all of the Protool Group shares, which then started 6 months of intense due diligence.

The Protool Group was finally sold on the 30th June 2022, 13 years after the shareholders had bought the Fareham site, then called Talana Plastics.

The sale gave a significant return on initial investment to the shareholding team and is an achievement that I am very proud.

What was the greatest challenge Covid posed to the business and how did you overcome it?

At the time of the Covid pandemic, I was Managing Director of The Protool Plastics Group, and we faced a much different challenge to most companies.

Whereas a lot of Managing Directors were looking at cutting costs and furloughing staff The Protool Plastics Group saw sales increase significantly with no more than a few days warning.

This meant increasing injection moulding and assembly staff numbers by over 50% between March and April 2020 while trying to meet the ever-changing government guidelines on social distancing and safe working practices.

The workforce on both sites were amazing and really rose to the challenge set by our customers for huge amounts of PPE.

However, it was not just our PPE customers that needed urgent production. Two of our major lighting customers won contracts for the Nightingale Hospitals so volumes were increasing across our complete customer base.

Looking back, it was a scary time for all key workers, leaving their homes each day to travel to work via empty roads and deserted streets.

No matter what your personal view of the pandemic is now, it should be acknowledged that the people who went out into the unknown each day in those early days of 2020 should be thanked for their efforts.

You’re exhibiting at this year’s Interplas exhibition – what can visitors expect to see on your stand?

With Interplas celebrating its 75th anniversary, we are excited to be involved and The Advanced Plastics Group can be found on stand A40M.

CEO Chris Pearson and I have a combined 80-year plastic industry experience and will be on hand to answer all technical, sales and commercial questions.

The directors and staff of The Advanced Plastics Group are very proud of the business and we strongly believe that we are the best in the UK.

This thought is backed up by a PIA panel of judges that awarded The Advanced Plastics Group as the current Processor of the Year.

We will showcase a significant array of moulding and post-mould processes at the NEC, demonstrating the depth of knowledge available to current and new customers.

We are also hoping to meet customers looking to ‘RESHORE’ production back to the UK where we can demonstrate significant experience in the, Hull, Fareham and Manchester sites.

The recent pandemic and war in Europe have demonstrated the lack of flexibility in long supply chains and we hope to see a continuation in a more localised approach.

What’s the best thing to happen to you since you were last in the HotSeat?

During the pandemic foreign travel restrictions, my family and I went on holiday to the Lizard Peninsula in Cornwall during the hottest week since 1976. While there, my daughter Mia and I went surfing at the Dan Joel Surf School at Poldhu Cove and it was great fun.

On return to the North East we have continued to surf at Long Sands Beach Tynemouth, always followed by several cups of hot chocolate at the beach café.

There’s nothing like the North Sea in March to sharpen the mind!

Get more news from The Advanced Plastics Group here.

Advanced Plastics

+44 (0) 1482 823038

Website

Email