Nippon Sheet Glass Co has partnered with Swindon-based 3D printing company Scaled to produce a lightweight, cost-effective automotive glass checking jig using additive manufacturing, replacing the previous aluminium solution.

As one of the world’s leading glass and glazing product manufacturers and suppliers, the Nippon Sheet Glass Co (NSG Group) is on the cutting edge of glass and glazing production. It already carries out the efficient manufacture of automotive glass products but saw an opportunity with Scaled to explore an innovative new way of manufacturing the jigs used to check its products.

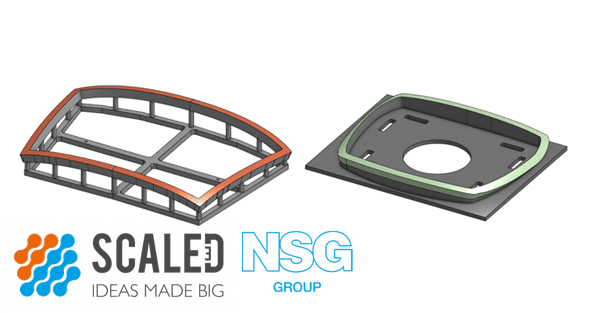

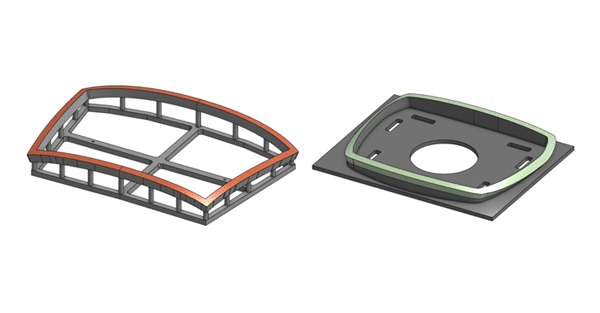

Due to the scale of components that the NSG Group manufacture, the company approached Scaled with the ambition of using its large-scale 3D printing equipment to print the checking jigs in full. The existing method of manufacture is to CNC mill billet aluminium to shape, which, due to the size of the jigs, can be costly and cause the jigs to be heavy and difficult to manoeuvre.

After discussing the NSG Group’s needs and expectations for the jigs, the two companies worked together to develop a solution. With the NSG Group’s tooling team sharing their expert knowledge of their processes and Scaled offering its expertise and experience in large-scale printing, the teams arrived at a design optimised for 3D printing.

The design was selected in order to maximise structural integrity while minimising the weight and material usage in the final part. The reduction in material use also has the desirable side-effect of reducing the cost of the final part.

There is development work to be done to roll out the process further within the NSG Group. The team notes that other business areas could benefit from the time and cost savings associated with working with Scaled, such as engineering and new product development.

Given the positive experience had by the NSG Group and satisfactory cost savings over traditional milled checking jigs, Scaled is laser-focused on helping more companies to develop their own large-scale 3D printed jigs and fixtures.

Click here to read the whitepaper on the approach Scaled takes when developing jigs and fixtures for customers.