As part of Inoplas’ continued investment programme in skills, equipment and facilities, they have expanded their CAD modelling capabilities.

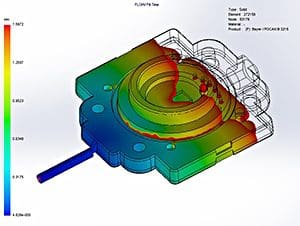

Inoplas have added a third Solidworks seat to increase the capacity of their design engineering team. The additional seat of Solidworks has plastics mould flow simulation, allowing them to go further in validating their designs before going to manufacture.

Inoplas have made this investment as a result of high demand from their customers for advice in the development of new products, especially in complex overmoulds and metal replacement scenarios. The software means that they can reduce design lead times and, as their tooling becomes ever more complex, they are able to brief toolmakers more accurately, to minimise tooling adjustments.

Solidworks Plastics sits alongside Inoplas’ existing CAD, 3D printing and 3D scanning capabilities and extends their ability to take new products the whole way from design to production. Find out more about their capabilities.