The de-moulding stage during the injection moulding process can be optimised through the use of an ejector delay unit. The Read More

Tags :hasco

At the upcoming FAKUMA, HASCO will present numerous new and further developments from the fields of Mould Base and Hot Read More

Quality management plays a major role in consistent product quality, and that applies particularly to tool and mould-making. The key Read More

The geometry of a planned injection-moulded component defines the complexity and the amount of work involved in designing and producing Read More

Upon entering the historic Schützenhalle in Lüdenscheid, Germany, guests were met with HASCO’s history. In the tunnel-like Read More

HASCO hot runner, a growing, innovative supplier of hot runner systems, has increased its presence in Latin America with the Read More

A lot of things in the mouldmaking industry have become a matter of course and the processes for mould production Read More

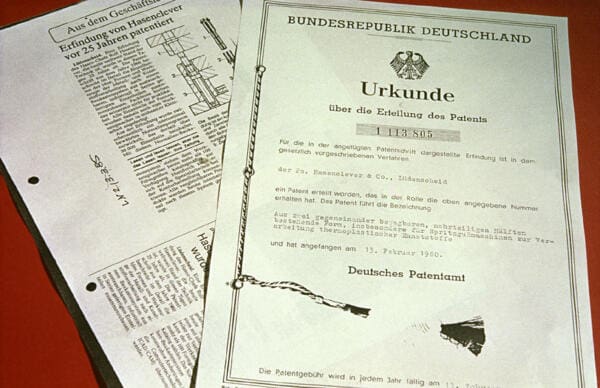

The HASCO story began in 1924, when the company’s founder, Hugo Hasenclever, made the first moulds for processing the still Read More

Over time, an injection moulding company quickly accumulates a considerable number of injection moulds, which are initially stored after a Read More

The fact that digitalisation has become indispensable in mould making and hot runner technology in order to optimise processes and Read More