In this blog article, RJG Technologies outline seven ways to lower your injection moulding costs so you can improve your Read More

Tags :rjg technologies

Some may ask: Why bother with a cushion if you monitor peak shot volume? In reality, a consistent melt cushion Read More

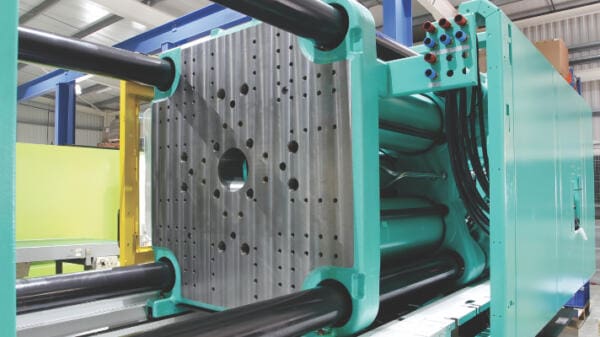

Clamp force is one of the most overlooked portions of the injection moulding process. How many times have you walked Read More

Putting a sensor anywhere in a tool can give you some form of data, but it may not be value-added. Read More

RJG Technologies’ eDART® system is one of the most comprehensive and powerful process monitoring systems for injection moulding applications. Gain Read More

In an industry full of grey areas and black books, what is “right” anyway? John Lobozzo, Technical Sales Engineer at Read More

In the plastic injection moulding industry, we work with materials that are byproducts of oil refinement and moulds made of Read More

Following months of conducting its training courses online, RJG Technologies is delighted to be able to welcome the public back Read More

For technical recruiter Sierra 57 to be best equipped to source the right candidates for their clients, they have invested in Read More

Managing Director, Richard Brown, will be stepping down from his post on 31st December. Richard believes now is the right Read More