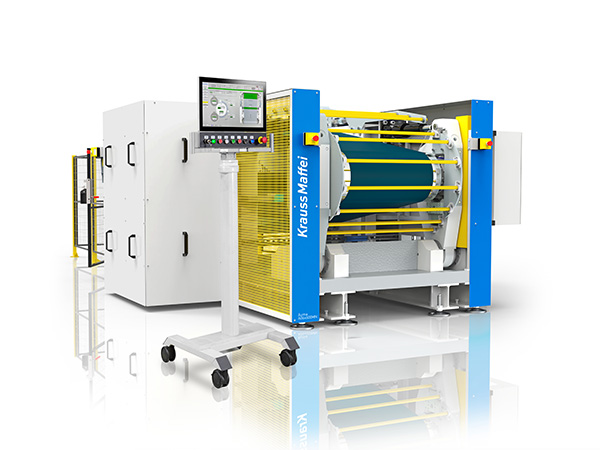

As a pioneer in designing and manufacturing continuously operating Auma rotary presses, KraussMaffei now continues a decades-long tradition by launching a completely new development. KraussMaffei’s new Auma series not only enhances productivity but is easy maintenance.

Continuous rubber sheet vulcanisation is certainly the best-known Auma application but by no means the only one. The Auma can equally be used for producing composite materials made of plastics and fabric for roofing sheets or floor coverings, as well as for welding, embossing, or laminating plastics film and sheets. The operating principle of continuous rotary presses is the ideal solution for a wide range of applications. Against this background, KraussMaffei now introduces a completely new Auma series offering a true value proposition for users.

The main advantage of the Auma operating principle over discontinuously operating platen presses consists in constant production conditions. The Auma ensures constant temperature, pressure and residence time values to avoid product quality variations, unevenness, or undesired transition marks. That’s reason enough why the Auma has firmly established itself in the market in the 0.5 to 20mm thickness range.

Enhanced productivity

With the new series comprising four models with heating drum diameters of 60, 100, 150 and 200cm, KraussMaffei launches a modularised machine solution. Designed for uncompromising productivity and maximum efficiency, these rotary presses impress by their flexibility and user-friendliness. All four Auma versions are available in three working widths ranging between 1.3 and 2.5m and two different belt designs. In addition to steel belts that are suited for many applications, KraussMaffei offers rubberised steel mesh belts for extremely pressure-sensitive or very thin materials.

The operating temperature of all Auma versions is between 80 and 220°C. The new series also comprises a special version designed for process temperatures of up to 340°C. Optimised temperature distribution across the heating drum width and optional temperature control ensure maximum accuracy and consistency in the entire production process while reducing overall energy requirements. Another plus point of the 60 and 100 Auma sizes is the increase of the process pressures to 10 bar. The two larger machine versions (150 or 200cm drum diameter) continue to operate at a pressure of 8 and 6 bar.

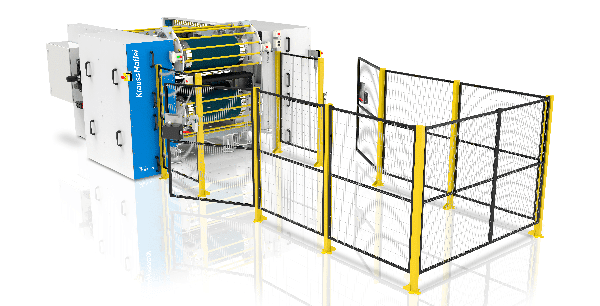

Easy maintenance

Janina Roesch, Application Owner Flat & Foam Products at KraussMaffei, explains why this technology ensures easy maintenance:

“The Auma core components are the heating drum, three reversing rolls and a pressure belt. The pressure belt is wrapped around a large part of the drum circumference while under high tensile stress and presses the material to be vulcanised, welded, or compressed against the heating drum. The easy access to the heating drum and reversing rolls enables the effortless and fast replacement of a worn pressure belt. Stable operation, long service intervals, reduced downtimes and conveniently priced spare parts ensure maximum cost-effectiveness over the entire service life.”

Thanks to KraussMaffei’s proprietary software (available as a Basic or Advanced version for the Auma), functionalities such as data recording, quality management and connection to interfaces of upstream and downstream equipment are incorporated as standard features.

Janina Roesch added:

“Having revamped the complete Auma series, we are pleased to offer our customers an established and proven machine technology in a modern design with a wealth of technical highlights. The smallest model with a heating drum diameter of 60cm represents an ideal solution for research and development applications and is now available for customer trials in our R&D centre.”

For more information, visit www.kraussmaffei.com/en/home.