The Wittmann Group will present its latest range of injection moulding technology, automation and auxiliaries to visitors of the Swiss Plastics Expo in Lucerne, from January 21st-23rd.

The main theme of the presentation at the Swiss Plastics Expo is to showcase intelligent machines with adaptive algorithms, which adjust themselves to various ambient conditions. This will be demonstrated with an all-electric EcoPower 55/350 equipped with the software packages HiQ-Flow®, HiQ-Melt and HiQ-Metering.

HiQ-Flow® is a material viscosity-controlled injection control system, which compensates the effect of temperature and batch influences on material viscosity and thus ensures reliable, consistently good quality of the injection-moulded parts.

HiQ-Melt is a method of monitoring material quality, which enables easy detection of deviations in material quality by measuring the energy consumed in the plasticizing process.

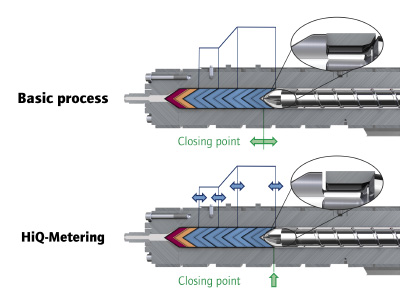

HiQ-Metering designates active closing of the check valve to ensure that precisely the necessary quantity of material is injected with every shot to achieve extreme consistency in part weights.

A W918 robot from WITTMANN, the temperature controllers of the TEMPRO plus D series, the gravimetric blender GRAVIMAX G14, the segmented wheel driers ATON plus H, as well as the TEMI+ MES solution, are integrated into the machine’s UNILOG B8 control system via WITTMANN 4.0. The electronic mould datasheet will also be used on UNILOG B8. The production cell linked together via the WITTMANN 4.0 router is thus able to check whether the connected auxiliaries are sufficient for the selected product data set, or if additional equipment is needed.

On the EcoPower 55/350, polycarbonate clothes pegs will be manufactured with a 4-cavity mould supplied by Lechner, Austria.

The second machine exhibited at the Swiss Plastics Expo is a MicroPower 15/10 specially designed for injection moulding micro parts, equipped with a rotary table, an integrated WITTMANN Scara robot W8VS2 and a camera for optical parts inspection. On this machine, micro bearing housings are manufactured from POM using a 6-cavity mould with tunnel gating supplied by Küng, Switzerland.

WITTMANN Automation and Auxiliaries

In addition to the auxiliaries installed on the injection moulding machines on display at the fair, WITTMANN will present various stand-alone solutions from its extensive range to trade visitors at the Swiss Plastics Expo 2020.

In the area of automation, the newly developed WITTMANN robot WX138 with the new R9 control unit will be showcased. The WX138 is equipped with a 950 mm X-axis. A completely new concept for the Z-axis with an internal tooth belt enables an extremely compact design. Also worth mentioning is the significantly increased rigidity of the vertical profile developed by WITTMANN. Compared to similar systems, the rigidity in the direction of the demolding stroke has been increased by 50%, and in the direction of the main carrier (Z-axis) by 100%.

In the areas of auxiliaries, the new TEMPRO plus D100 temperature controller is a special highlight of the presentation at the Swiss Plastics Expo. The TEMPRO plus D100 belongs to the range of temperature controllers which can be used as components for WITTMANN 4.0 production cells. This means that the TEMPRO plus D100 can be fully integrated into the control system of a WITTMANN BATTENFELD injection moulding machine. The new temperature controller is capable of 9 kW heat output and stands out by its magnet-coupled stainless steel pump, which ensures sufficient flow quantities. The pump capacity is 0.5 kW, with a maximum flow quantity of 40 l/min and a maximum pressure of 4.5 bars. The TEMPRO plus D100 is equipped with a wear-resistant, maintenance-free flow quantity measurement device as standard.

And finally, there will be an S-Max 2 screenless granulator on display, which is suitable for grinding hard and fibreglass-reinforced plastics.

Visit Wittmann at the Swiss Plastics Expo in Lucerne from 21st to 23rd January 2020, in hall 2, booth B 2041.